STATISTICAL PROCESS CONTROL OVERVIEW

Manetek, Inc. is committed to maintaining manufacturing processes in a state of Statistical Process Control, ensuring the machining of products meet specified requirements.

What is SPC?

Statistical Process Control is a set of techniques that are used to monitor processes in order to provide feedback. The feedback is used to maintain and improve the capability of the process. SPC, like traditional inspection, is an approach used to ensure product conformance. However, SPC is also used to control the process by signaling when adjustments may be necessary. Some techniques associated with SPC include histograms and control charts.

A control chart is the tool developed to monitor the variation in a process. The control chart indicates if the process is in a state of control or going out-of-control. The control chart is basically the histogram turned on its side with the observations stretched out over time. This allows the operator to monitor the trends going on in the process.

The control chart has upper and lower "out-of-bounds" limits. These limits and the center line are used to help evaluate trends in the process. The value of the upper control limit is calculated by adding the process average to 3 times the process standard deviation or upper part tolerance in thousands of inches.

Upper Control Limit (UCL) is a line drawn all the way across the chart at this value. The Lower Control Limit is the reciprocal calculation of the (UCL) process. The control chart uses simple rules to signal when conditions may have changed. Some commonly used rules are:

- Any point on or outside a Control Limit.

- A trend of consecutive points moving in the same direction, either upwards or downwards.

- Consecutive points above or below the centerline.

- Non-random pattern of points.

This tool is a prime force in discovering and acting to remove assignable causes to continuously improve processes. Once it has been determined that a process is acting out of control, efforts are made to determine what the cause is. This is usually handled by a team of operators, supervisors, and management.

WHAT CORRECTIVE ACTION DOES FOR MANETEK, INC.

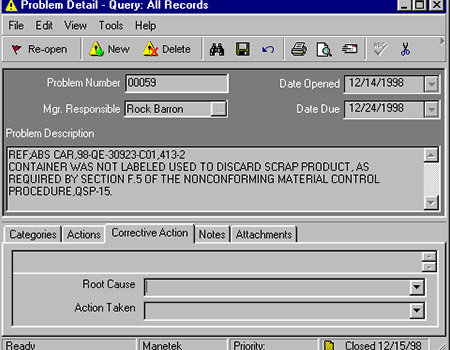

Our Corrective Action system is a general purpose database for tracking information about problems, complaints, or projects that need certain information, as well as the action items that people are performing to complete these problems, complaints, or projects. In its fundamental sense, the subject of Corrective Action is the systematic identification and elimination of problems. The database is used to track complaints and problems, both at the departmental level and company-wide.

At Manetek, Corrective Action is a workgroup productivity enhancement tool. It helps people collaborate to resolve issues and gives visibility to open issues. Have you ever sent an email to someone asking them to do something for you? People often assign an action to someone by email and then a month later wonder what ever happened. Our Corrective Action System lets you assign an action, then catalog and record the results to maintain high visibility for the existence of the action. By providing high visibility, there is less opportunity for an issue to be ignored or forgotten. Everyone is reminded of the activities that need to be performed.

Benefits of Corrective Action Management System

Corrective Action is the systematic identification and elimination of the root causes of our problems. This means that our system is in place to identify problems as well as their root causes. Since problems exist at all levels, the system should be specific on the area to be addressed.

Systematic Identification of Problems

Some companies have dedicated Corrective Action Engineers, who constantly monitor Scrap, Rework, Supplier, and Production Trend/Yield Data, which may affect Quality, Profit, and Schedule.

The root cause of a problem is sometimes difficult to determine. When a defective part arrives from a supplier, is it enough to say that the root cause is "supplier," or should the extra step be taken to determine that the root cause is "Worn Tooling" at the supplier?

Unless the true root cause is identified and eliminated, the problem will never go away. Many people misuse the term "Corrective Action" to describe the temporary fix which did not eliminate the root cause.

The elimination of problems is a team effort, often requiring top management support. We have formal Management Reviews, consisting of a manager from each department. These reviews are on a regular basis and require mandatory participation of all members.

Communication is the key to the success of our corrective action effort. Everyone must know what the problems are and everyone must contribute in solving them. The resolution of each problem is the responsibility of the individual with the proper authority and resources.

Systematic Elimination of Problems

The individual actions (investigation, change implementation, and follow-up) must be assigned to the persons who have the capacity and accountability to complete them.

The process of identifying and eliminating problems should continue indefinitely. As the larger problems are eliminated, smaller ones will always take their place. The good news is that the corrective action process almost guarantees measurable improvements in quality and profit. Your efforts will be well rewarded.